Connections

Use solder-cup connectors wherever possible. It's easier than crimping and more reusable. Don't strip the wire any longer than needed to fill the solder cup.

When you have to crimp connections, use a ratcheting crimper if you can get one. These won't let go of the connector until it has been fully crimped.

It is possible to make what looks like a crimp on small pins using pliers. Don't do this. They don't have the right shape and the wire will pull out with a little force.

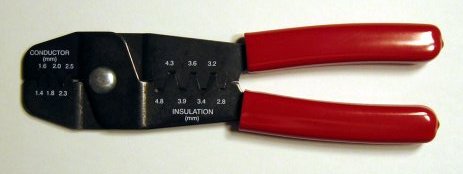

For some reason, good crimping tools for small connections like pin header and D-Sub/CPC contacts are insanely expensive. Even the hand tools recommended by Digi-Key cost hundreds of dollars (I suspect there is a high margin on these). There are a lot of cheap tools for these kinds of pins, like this one:

As far as I can tell, the best way to use this tool is to throw it away and buy a better one. I have been unable to make an acceptable crimp with it. However, there is a tool made by Molex which looks similar and does work:

This tool is Molex #63811-1000 (Digi-Key WM9999-ND, Mouser 538-63811-1000). It costs about $40 from Mouser and $50 from Digi-Key. It supports a lot of sizes and actually makes good crimps. The main disadvantage is that it doesn't ratchet, so you have to squeeze really hard and assume you did it right. There is some visible difference in the shape of the crimping parts of these two tools, but the Molex tool produces vastly better crimps.